-

TAGUTI EDM Brass Wire (Most Applicable & High Cost-performance)

This TAGUTI brass wire draws its properties from high grade alloy. The excellent tensile strength of the wire, as well as the exceptional surface property, improves significantly the cutting precision. It is made by normal brass alloy to be used normal machine condition at WEDM. The auto threading rate can be raised whether the threading mechanism is pipe type, water jet type, or anneal cutting type because the wire is very straight. Also, the surface is treated to prevent brass powdering. This TAGUT wire is suitable in particular for Fanuc, Hitachi, Mitsubishi and Sodick machines. In order to meet the market demands, TAGUTI introduces this brass wire with higher cost-performance.

Suitable for automatic threading

Exceptional tensile strength

Extreme cleanness of the wire

High reliability during machining

Obtains excellent surface finish

Recommended for high precision workBrass Wire Variety Characteristics Diameter KG/Roll TAGUTI Core Cu Zu35 Ф0.20㎜ 5.0KG EDM Brass Wire Tensile strength 900N/㎜2 Ф0.25㎜ (Hard) Elongation <3%(Hard) Conductibility 20% IACS Surface color Golden Zinc Coated Wire From TAGUTI (Brass Core & Zinc Coating)

This is a coated TAGUTI brass wire developed in response to a market demand for high quality and precision wire. It is particularly suitable for applications with special requirements for extremely fine precision cuts. The special coating ensures a very clean finish along the cut surfaces as well as a high performance in terms of cutting speed. Compared with brass wire, this TAGUTI type coated wire has faster cutting speed and improves surface roughness and dimension precision. Also, this zinc coated wire guarantees stable conductivity.

High precision in cutting

Excellent surface finish – Ra 0.1μm

Suitable for automatic threading

Cutting speed up to 20% faster than brass wire

Uses standard zinc coated technology

High speed erosion, up to 10% faster than brass wireCoated Wire Variety Characteristics Diameter KG/Roll AGIE Core CuZu37 Ф0.10㎜ 1.6KG Cobra CUT A Coating Zu Ф0.15㎜ 6.0KG Tensile strength 900N/㎜2 Ф0.20㎜ 16KG (Hard) Ф0.25㎜ Elongation <2% Conductibility 21% IACS Surface color Silvery Coated Wire Variety Characteristics Diameter KG/Roll AGIE Core CuZu20 Ф0.25㎜ 16KG Cobra CUT D Coating CuZu50 Tensile strength 800N/㎜2 (Hard) Elongation <3% Conductibility 29% Surface color Brown Coated Wire Variety Characteristics Diameter KG/Roll Charmilles Core CuZu37 Ф0.10㎜ 3.7KG SWA Coating Zu Ф0.25㎜ 15KG Tensile strength 900N/㎜2 (Hard) Elongation <2% Conductibility 21% Surface color Silvery Coated Wire Variety Characteristics Diameter KG/Roll Charmilles Core Cu Ф0.25㎜ 3.7KG SWX Coating CuZu50 Ф0.30㎜ 8.0KG Tensile strength 510N/㎜2 (Half Hard) Elongation <8% Conductibility 21% Surface color Brown -

-

TAGUTI® MB-9L Mixed bed resin for low-speed wire-cutting

Product Information:

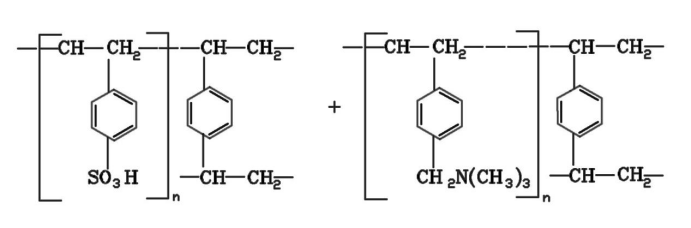

TAGUTI MB-9L mixed bed resin dedicated for low speed wire cutting is ready-to-use resin comprised of gel-type strongly acidic cation exchange resin and strongly basic anion exchange resin. It is made with special resin used for high transition and special purification process as well as mixed and compounded according to specific chemical equivalent. MB-9L is appropriate for low speed wire cutting electrical discharge maching, condensate polishing system preparation of high purity water with the major purpose of removing ions and metallic oxides and it is featured by high purity refining, large working exchange capacity and long service life, etc.Chemical Structural Formula:

Basic Characteristics:

Ionic form H﹢/ OH- Functional group Sulfuric acid group/quaternary amine group Matrix Crossliked polystyrene Structure Gel type Appearance Brown yellow, transparent spherical particles Physical and Chemical Properties

Water content % 52-57 Particle size range ≥95% 0.315-1.25 Uniformity coefficient ≤ 1.6 Bulk density g/l 700-800 Wet real density approx g/ml 1.13 Transition rate Cation resin H-type transition rate ≥, % 99 Anion resin OH-type transition rate ≥, % 90 Recommended Operating Conditions

Operating temperature max ≤ ℃ 60 Operating flow rate BV/h 20-90 Bed depth ≥ ㎜ 600 Storage temperature ℃ 0-40