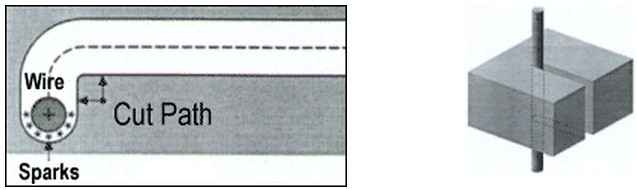

Wire EDM machining (also known as “spark EDM”) works by creating an electrical discharge between the wire or electrode, & the workpiece. As the spark jumps across the gap, material is removed from both the workpiece & the electrode

To stop the sparking process from shorting out, a non conductive fluid or dielectric is also applied. The waste material is removed by the dielectric, and the process continues. TAGUTI provides the solutions of wire edm filters